Building Mechanical Advantage with the CLUTCH // CMC Fundamentals

In this CMC Fundamentals Video, we will be building several different types of Mechanical Advantage or M/A Systems using the CMC CLUTCH by Harken Industrial. The CLUTCH will serve as a fixed pulley and the progress capture device in all the M/A systems shown. The only pulleys that can generate mechanical advantage in a system are the pulleys that move.

The second rope system that would function as the second system in a Twin Tension Rope System or as the Belay Line has been purposely left out of this video for clarity.

A simple pulley system or simple mechanical advantage is defined as a system in which all the mechanical advantage pulleys are moving at the same speed as the load.

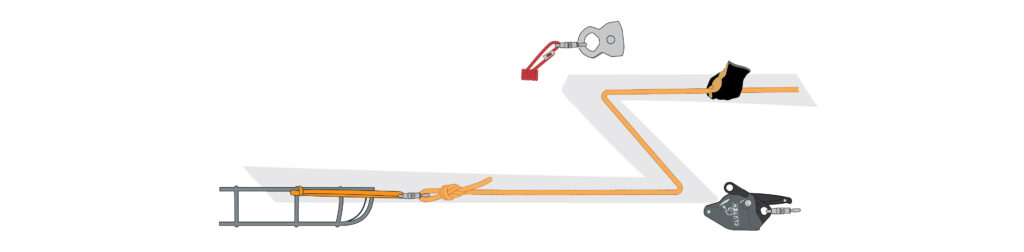

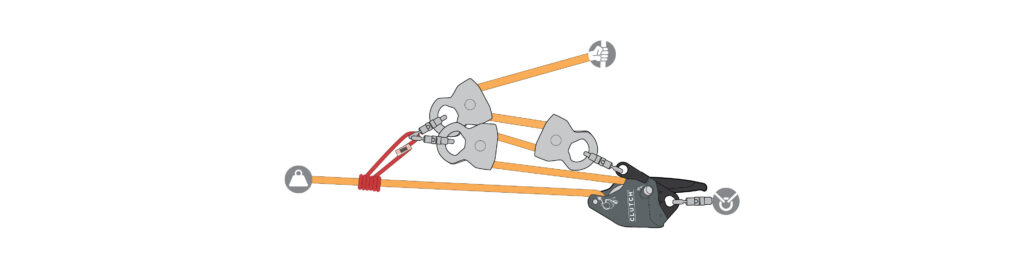

Simple 3:1 or Z-Rig

To build an efficient Simple 3:1 MA (also known as a Z-Rig) you will need a carabiner, a prusik cord and a pulley in addition to the CLUTCH.

- Start building the system by rigging the rope through a properly anchored CLUTCH.

- Attach a prusik cord to the mainline using a 3 wrap prusik hitch and dressing the hitch.

- Attach a carabiner and pulley to the prusik cord and lock the carabiner.\

- Run the rope through the swivel pulley and fully close the side plate. If you are not using a swivel pulley, you will need to rig the rope through the pulley and then attach it to the carabiner.

- Make sure the handle of the CLUTCH is placed in the stand-by position. You can haul through the CLUTCH with the handle in the stop position but that position adds unnecessary friction.

- The 3:1 MA is now ready to haul.

- To reset, loosen the prusik and pull the system forward using the carabiner as a handle. Do not reset the system by pulling forward on the prusik hitch itself, it is much more difficult and will prematurely wear out the prusik.

- When hauling with a 3:1 MA, 3 feet of rope to move the load 1 foot (3 meters to move the load 1 meter)

Z-Rig / Simple 3:1

Simple 3:1

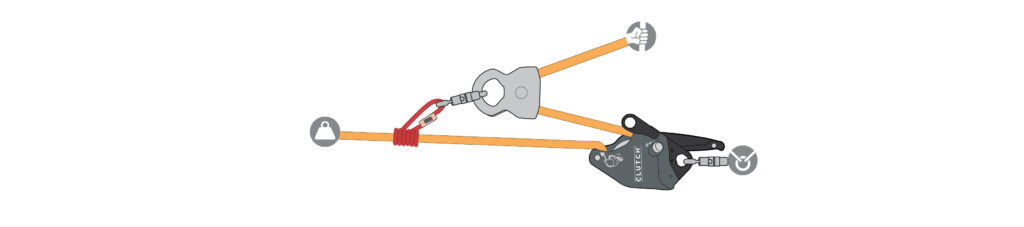

Simple 3:1 with a Change of Direction

- In addition to the Simple 3:1 in the last segment, a carabiner and a pulley will be added to the becket on the CLUTCH. We recommend using a swivel pulley when attaching to the becket to avoid any unnecessary torsion on the becket. Make sure the carabiner is locked.

- Rig the rope through the pulley, making sure the side plate is fully closed, and now the rope can be pulled away from the anchor or off to the side of the system

- Since the additional pulley is fixed, there is no additional mechanical advantage but actually adds friction and reduces the efficiency of the M/A

Simple 3:1 with a change of direction

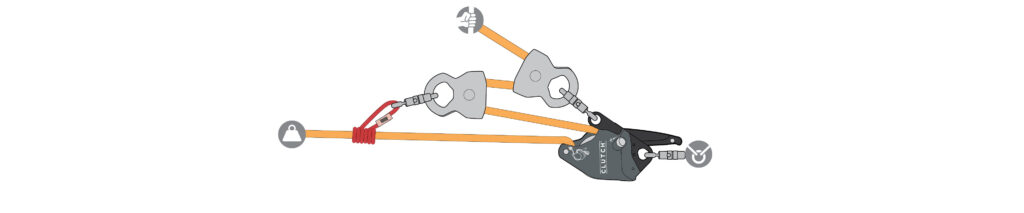

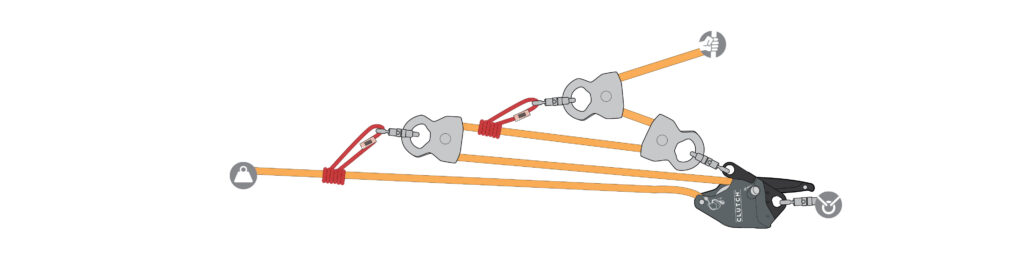

Simple 5:1

- In addition to the Simple 3:1 with a Change of Direction in the last segment, a carabiner and pulley will be added to the prusik cord on the main line. Make sure the carabiner is locked.

- Rig the rope through the pulley and make sure the side plate is fully closed.

- A double pulley can be used in place of 2 individual moving pulleys, but you will lose the ability to convert this system back quickly and easily to a Simple 3:1 M/A or to a Compound 9:1 M/A

- In this simple 5:1, 5 feet of rope to move the load 1 foot. (5 meters to move the load 1 meter)

Simple 5:1

Compound 9:1

- A compound pulley system or compound M/A is defined a simple pulley system pulling another simple pulley system. The amount of M/A is determined by multiplying the individual M/A systems; in this case 3:1 x 3:1 = 9:1.

- In addition to the Simple 5:1 in the last segment, prusik cord will be added to the haul side of the original 3:1 and moving the second carabiner and pulley that was added to create the 5:1 to the new prusik. Make sure the carabiner is locked.

- In this 9:1 MA, 9 feet of rope to move the load 1 foot. (9 meters to move the load 1 meter)

- The second 3:1 requires more resets since it moves 3 times faster than the 3:1 attached to the load

- The system is easily converted back to a simple 5:1 by reversing these steps

Compound 9:1

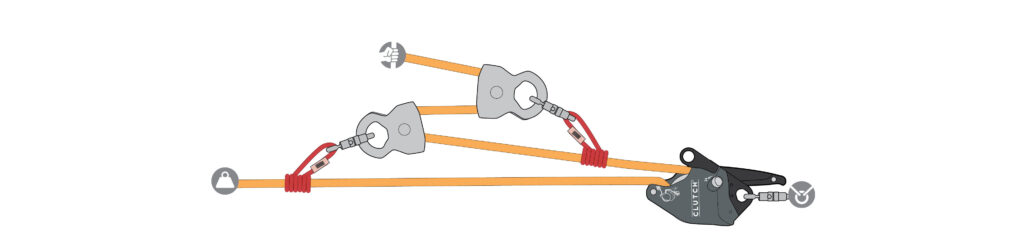

Complex 5:1

- A complex pulley system is defined as a system that is neither simple or compound. They

generally have at least one pulley moving towards other another moving pulley(s). - Start by building the simple 3:1 as shown in the first segment

- Attach a prusik cord to the free end of the rope exiting the CLUTCH using a 3 wrap prusik hitch and dressing the hitch

- Attach a carabiner and pulley to the prusik cord and lock the carabiner

- Run the rope through the swivel pulley and fully close the side plate

- The big advantages of a Complex 5:1 is that it requires less hardware to build; in this case the properly anchored CLUTCH, 2 prusiks, 2 carabiners and 2 pulleys. As a result of less pulleys in the system, it generally has less friction hence more efficient.

- In this system, the haul team is pulling away from the anchor which may be an advantage

- The disadvantage is that the system requires more resets because the pulleys are moving towards each other

- In this system, approximately 4 feet of rope will be pulled to move the load 1 foot. (4 meters to move the load 1 meter)

Complex 5:1

There are many other M/A systems, but these are the ones we find most useful and practical.