PRO Tip: Marking Rope and Webbing

It is desirable to mark rope and webbing for several reasons. First, ASTM F1740-96, NFPA 1858 and manufacturers recommendations all call for the service life of life safety rope and webbing to never exceed 10 years. It is difficult to remember when these soft goods are put in service so the marking the rope and webbing with the date of manufacture will assist with record keeping and inspections. Secondly, it is helpful to mark the length of the rope and for both operational convenience and to document the item in inspection logs.

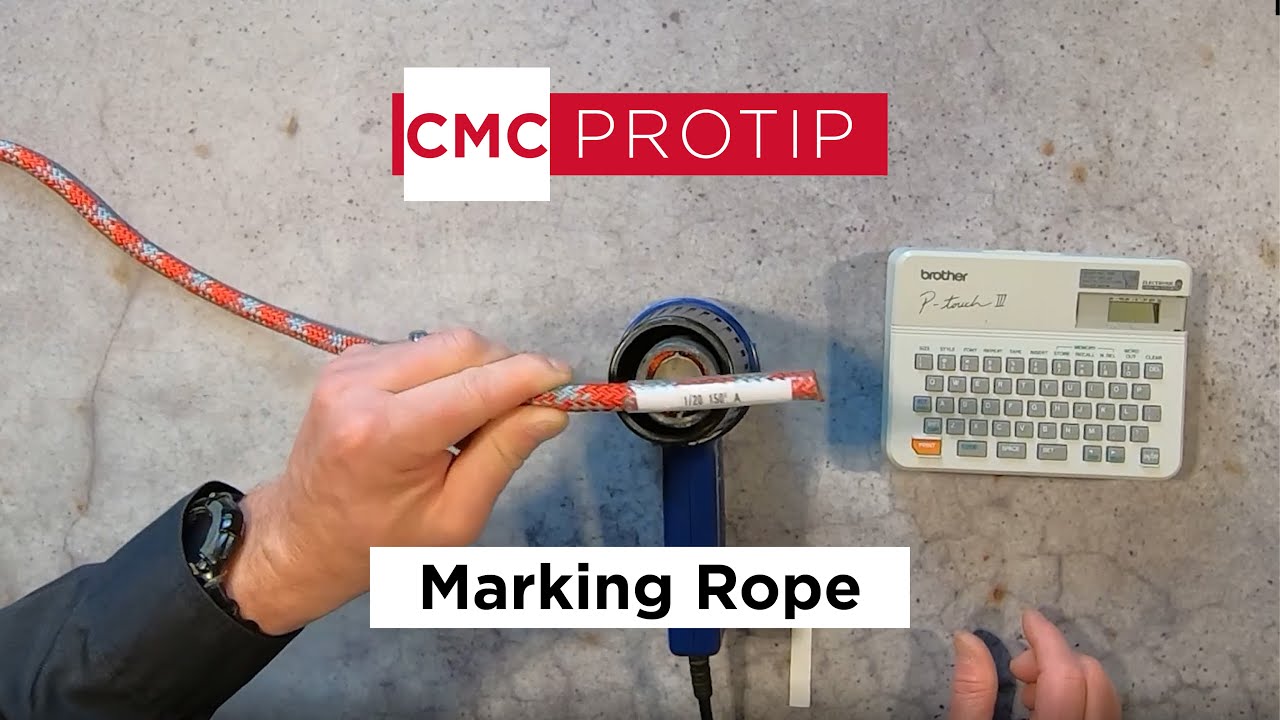

Life safety rope should also have each end marked with an “A” and “B” respectively. This allows for the ends of the rope to be routinely rotated in the bags to help even out the wear. This prevents one end from experiencing excessive wear while the other end of the rope is never used. The CMC School marks each of our life safety ropes with the date of manufacture, length of rope and “A” or “B” on a printed label affixed to the ends of the rope and then protected by placing a clear heat shrink tube in place to protect the label. It is important not to overheat the rope or label when shrinking the tube with a hair dryer or heat gun.

Webbing should also be marked in the center to make it easier to find the middle of the piece of web when tying redundant anchors and to start the daisy chain storage method. CMC recommends the use of a “Rub-a-Dub” brand laundry marker or a “Sharpie Laundry” brand marker to mark webbing. The reason for this recommendation is that there is a more consistent manufacturing process with less variations in solvent types being used in the ink formulas for these specific laundry style markers.